#precisionverified

ASTROFEIN Laboratory for Environmental Simulation

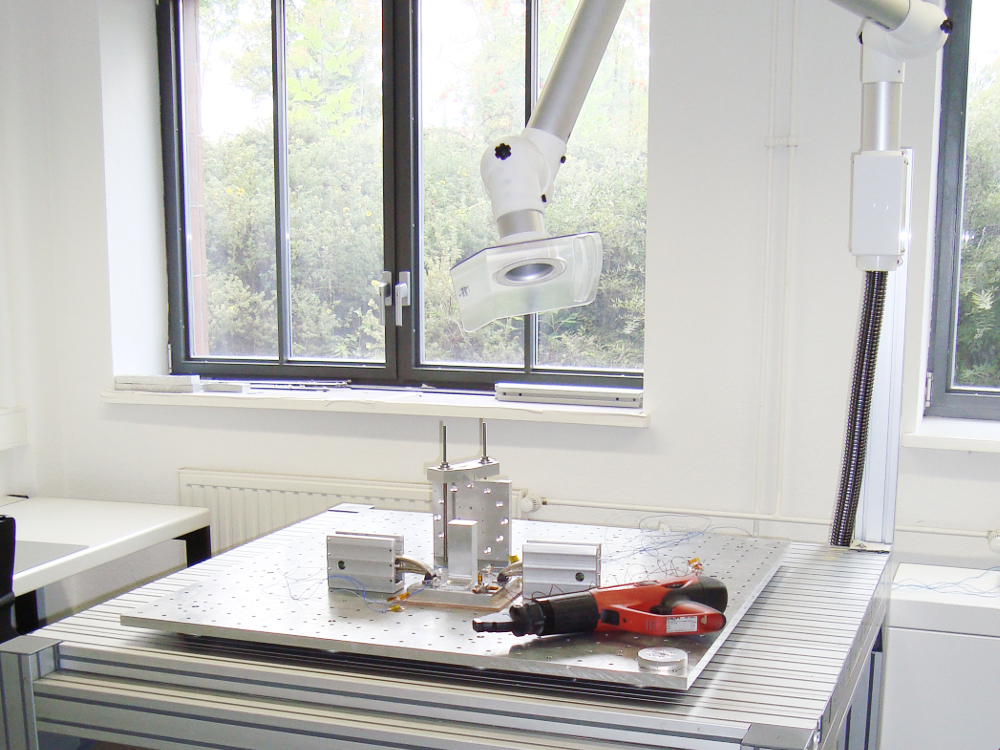

We offer mechanical and thermal tests in our environmental simulation laboratory. In addition to transport tests, our expertise also includes operational tests for equipment such as booms or plates as well as movement tests under special environmental conditions for examples low temperatures, artificially generated weightlessness.

According to customer specifications, we design and manufacture specific test set-ups and realise the required test set-ups. According to ECSS specifications, we test your products and provide you with a comprehensive test report. The company is certified according to DIN EN ISO 9001:2015 and DIN EN 9100:2018. An experienced team of test engineers is at your side during the entire test procedure.

Reasons for environmental simulation testing are:

Reduction of development and construction time of a product

Reduction of the time needed for corrections and rework

Avoidance of damage during transport

Avoidance of malfunction and failure

ASTROFEIN Vibration Tests

Vibration tests are used to test mechanical, electronic and electrical components and devices. The structural responses caused by vibrations are measured and provide information about the load capacity, service life and functional safety of the respective test item. In our test laboratory, various shaker systems up to 35 kN are available. We offer:

Sine Vibration

Random Vibration

Mixed SoR / RoR

Shock Classic/SRS

Force Measurement

Force Notching

ASTROFEIN Pyroshok tests

During the rocket launch, but also during later separation processes in space, space products and systems are exposed to certain shock loads. On our pyroshock test facility, a 1m² ringing plate, we simulate these shock-like influences. We can generate pyroshocks with shock loads of up to 8,000 g in a shock response spectrum. We offer:

Pyroshock

Classic Shock

MIL 883 Unit Tests

Transportation Tests

Automotive Tests

Standard and Customer Requirements

ASTROFEIN Thermal Tests

With our thermal tests, the function and material properties of a test specimen can be tested under the influence of temperature. Our thermal oven can run a temperature range from – 70°C to +180 °C and has a test chamber volume of 500 mm x 500 mm x 400 mm dimension. We offer:

Temperature Chamber

Temperature Environments from -70°C to +180°C

Thermal Balancing

Thermal Cycling

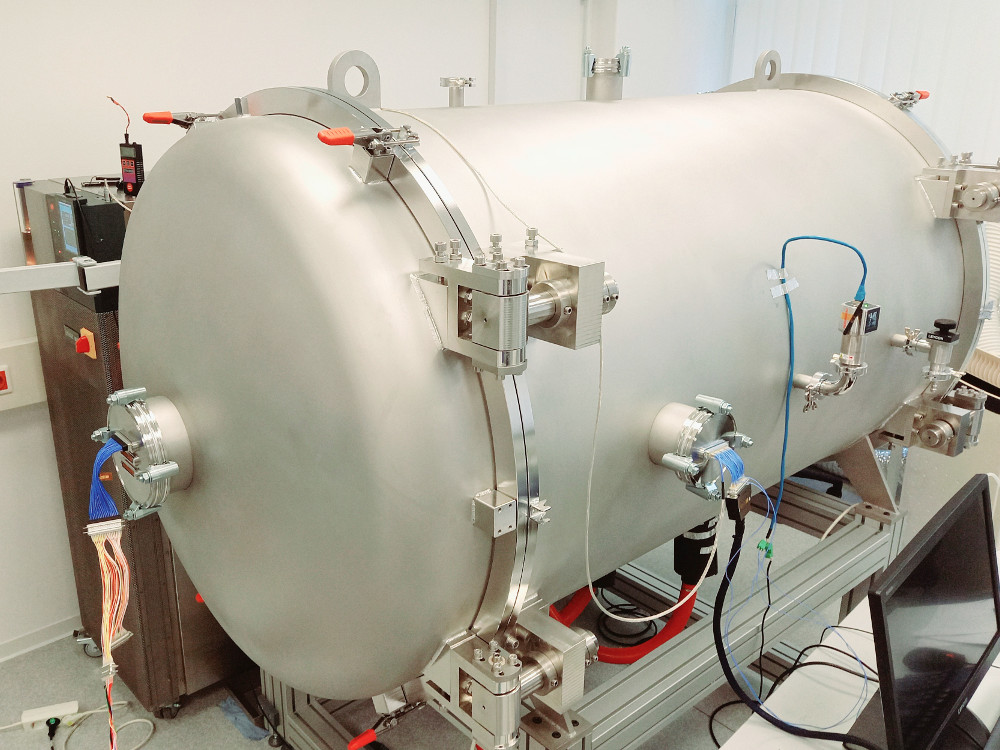

ASTROFEIN Thermal Vakuum Tests

In our thermal vacuum chambers we can generate a controlled high vacuum and perform thermal balancing, bake-out or thermal vacuum cycle tests. In addition to the obligatory pressure and temperature measurement, we offer our customers the possibility to perform optical infrared measurements in the range of 600 nm – 40 µm through a sight glass window. Various electrical feedthroughs in normal and high-frequency versions are available to lead data from the test object to the outside. We offer:

Thermal Vacuum Chambers

Vacuum Environment of less than 10 -5 mbar

Temperature Environments from -60°C to +150°C.

Thermal-Vacuum Balancing

Thermal-Vacuum Cycling